The samples whose high quality should be checked is often any of the varieties. It really should be dissolved in an appropriate diluent if it’s drinking water-soluble. Whether it is oil soluble, then it's dissolved in an acceptable solvent. Membrane filtration is utilized to test the following substances:

Aerobic and anaerobic bottles. A bottle made up of antimicrobial adsorbing resin is preferable to straightforward bottles. It is actually perfectly documented inside the scientific location that blood culture bottles have bad sensitivity for detecting mold.

This treatment is applicable to OOS effects of sterility test of complete product or service only performed during the microbiology laboratory.

By conducting an intensive RCFA, the workforce was capable to detect the root trigger for a style flaw while in the producing process. This led to your implementation of corrective steps, such as process modifications and enhanced good quality Command actions.

The failure Investigation of many various products and solutions includes using the subsequent instruments and techniques:

The investigation procedure should describe the phases in the investigation and recommended timing for completion of each and every phase.

We also provide streamlined validation expert services for making implementation much easier than ever right before. Like that, you could carry items to the individuals that need it, speedier.

" Discerning the worst case circumstance needs an entire knowledge of the product or service, its loading and its service surroundings. Prior to the solution getting into services, a prototype will generally bear laboratory testing which proves the solution withstands the worst situation state of affairs as anticipated."[6] Several of the read more tests accomplished on jet engines nowadays are quite intensive examining When the motor can stand up to:

Our membrane filtration method uses enclosed sterile units, making it possible for two samples of equivalent volume to filtered at the same time via two membrane filters.

Based upon the bioburden on the item, the described sterilization process parameters will consistently be effective in acquiring a predetermined Sterility Assurance Stage (SAL); and 2. The defined process parameters won't adversely have an more info affect on product and bundle efficiency.

It helps businesses keep away from recurring problems and minimize the overall price of failures. Repairing the foundation lead to is more practical than consistently treating the signs.

Finished product or service samples will have to go through a fourteen-working day incubation period of time prior to getting cleared for release onto the marketplace. Anything at all a lot less than a one hundred pc pass level can relegate an entire batch, preventing it from achieving the those who rely upon it.

Sterile producing is a significant process that requires meticulous attention to depth and adherence to strict aseptic procedures.

We try our best to generate this site consumer-helpful and resourceful with well timed/updated information regarding each pathogen, ailment caused by them, pathogenesis, and laboratory diagnosis.

Neve Campbell Then & Now!

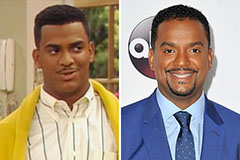

Neve Campbell Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!